Most PPR water pipe leakage problems are caused by poor welding. Welding quality is a crucial part of PPR water pipe installation. We have talked about the operating specifications for PPR water pipe welding before. Every water pipe installer should strictly follow the specifications.

Let’s look at standard welding first:

Let’s take a look at common welding problems:

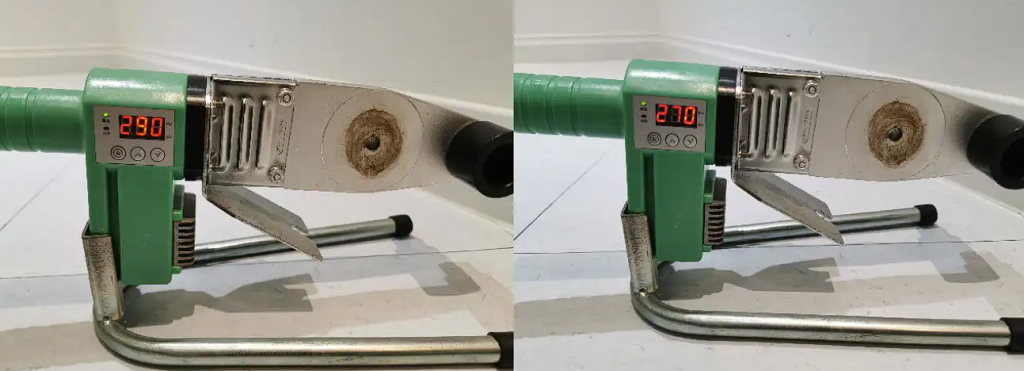

- The temperature of the welding machine is too high

We recommend using standard welding temperatures for welding pipes and fittings when welding PPR water pipes. If temperature-adjusted welding is used, according to the welding specifications, the temperature for welding PPR should be 260°C, and it is best not to exceed 270°C. Excessive temperature will cause the PPR material to become too thin and soft, or even partially carbonized, causing welding problems.

- Aging of welding die head

The die on the hot melt welding machine for PPR water pipes is made of Teflon paint. Teflon has low surface energy, so the melted PPR will not stick to it. However, in a long-term high temperature environment, Teflon, as a polymer material, will also experience aging, which will not prevent PPR from adhering. Many workers do not clean the die head when welding PPR water pipes, and they do not have the habit of regularly replacing the welding machine die head. This makes it difficult to ensure the welding quality of PPR water pipes.