When using a butt welding machine, sometimes the PE pipe hydraulic hot-melt butt welding machine cannot pressurize, resulting in the inability to perform normal butt welding operations. This situation has brought great trouble to the construction of the project, so the problem needs to be found and solved as soon as possible.

Possible cause analysis

If the PE pipe hydraulic hot-melt butt welding machine cannot pressurize, it may be due to the following reasons:

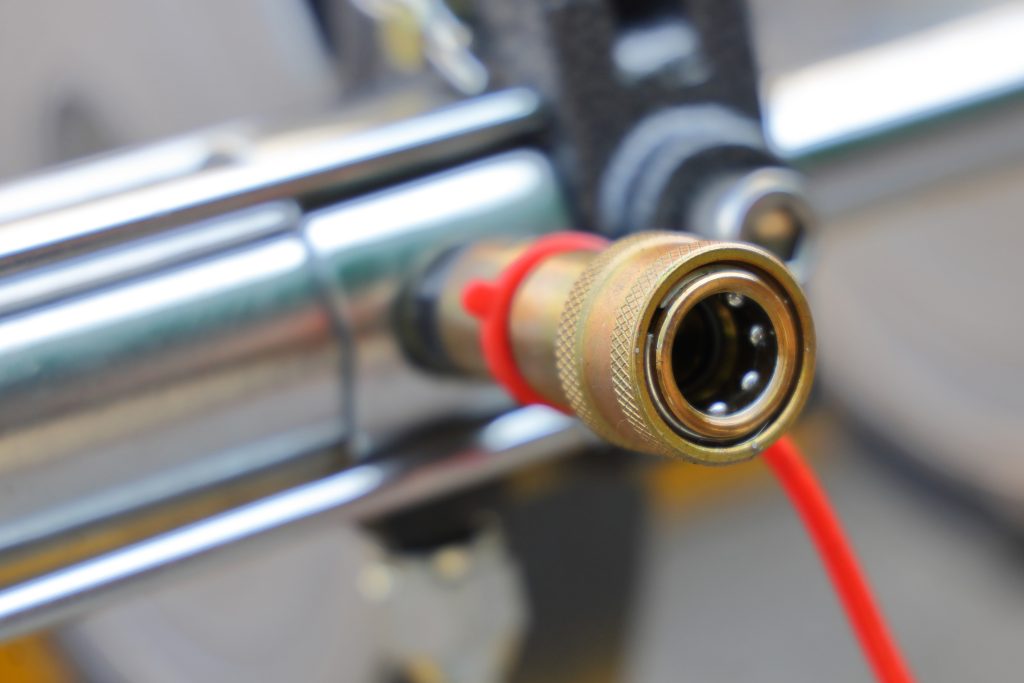

- Hydraulic system failure: The hydraulic system of the PE pipe hydraulic hot-melt butt welding machine fails, such as hydraulic oil leakage, hydraulic pump failure, etc.

- Electrical system failure: Electrical system failure, such as control panel failure, solenoid valve failure, etc.

- Mechanical system failure: Mechanical system failure, such as piston seal wear, welding head damage, etc.

Solution

In response to the above possible reasons, the following measures can be taken to solve the problem that the PE pipe hydraulic hot-melt butt welding machine cannot pressurize:

Hydraulic system failure

If the problem is caused by a hydraulic system failure, you first need to check whether the hydraulic oil in the hydraulic tank is sufficient. If it is insufficient, you need to replenish the hydraulic oil. Secondly, you need to check whether the hydraulic pump, hydraulic valve and other components are normal. If there is damage or failure, it needs to be replaced in time. or repair.

Electrical system failure

For electrical system failures, after checking whether the control panel, solenoid valve and other components are normal, you can solve the problem by reconnecting the power supply and checking whether the circuit is damaged; if the electrical components are seriously damaged, you need to replace them with new ones. .

Mechanical system failure

If the mechanical system fails, components such as welding joints and piston seals need to be inspected, and severely worn components need to be replaced in time. It is also necessary to check the lubrication of mechanical components to ensure smooth operation of each component.

Other things to note

When operating, attention should be paid to the working environment and operating temperature of the PE pipe hydraulic hot-melt butt welding machine to avoid environmental factors affecting the normal operation of the equipment. During use, the equipment must be serviced and maintained regularly to ensure that the equipment is in good working condition.

Regarding the problem that the PE pipe hydraulic hot-melt butt welding machine cannot pressurize, it is necessary to carefully analyze the specific situation and take corresponding measures in a timely manner to ensure the normal operation of the equipment and provide strong support for project construction.