Table of Contents

Introduction

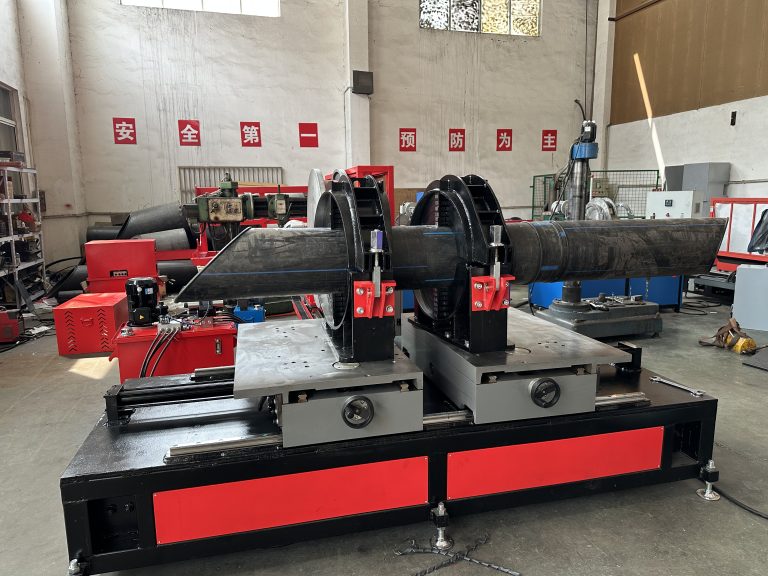

High-Density Polyethylene (HDPE) pipes are widely favored for their excellent performance and broad applications. Understanding the sizes and specifications of HDPE pipes is crucial for proper selection and installation. This article will detail the dimensions of HDPE pipes and provide relevant information to help users make the best choices for various applications.

Outline

- Standard Sizes of HDPE Pipes

- Importance of Size Selection

- Size Requirements for Different Applications

Main Content

Standard Sizes of HDPE Pipes

HDPE pipes are typically manufactured according to international standards to ensure compatibility and consistency across different applications. The main size parameters include outer diameter, wall thickness, and length. Here are some common standard sizes of HDPE pipes:

- Outer Diameter (OD): The outer diameter of HDPE pipes ranges from 20mm to 2000mm, depending on the application requirements.

- Wall Thickness: Wall thickness is proportional to the outer diameter, with common standards including SDR11, SDR13.6, and SDR17, where SDR stands for Standard Dimension Ratio. The lower the SDR number, the thicker the wall.

- Length: HDPE pipes are typically supplied in straight lengths or coils. Straight lengths are usually 6 meters or 12 meters, while coil lengths are customized according to specific needs.

Importance of Size Selection

Selecting the appropriate HDPE pipe size is critical for ensuring the system’s performance and reliability. Here are some key considerations:

- Pressure Rating: Different wall thicknesses of HDPE pipes have different pressure ratings. The appropriate wall thickness should be chosen based on the system’s operating pressure.

- Flow Requirements: The internal diameter of the pipe directly affects the fluid flow rate and velocity. The appropriate outer diameter and wall thickness should be selected based on the specific flow requirements of the application.

- Installation Environment: In confined or complex installation environments, choosing the right pipe length and diameter can simplify the installation process and improve construction efficiency.

Size Requirements for Different Applications

HDPE pipes are widely used in municipal water supply, sewage treatment, agricultural irrigation, and industrial pipelines. Different applications have different size requirements:

- Municipal Water Supply: Typically, larger diameter HDPE pipes are selected to ensure adequate water supply capacity. Common specifications include OD160mm to OD1000mm.

- Sewage Treatment: The appropriate outer diameter and wall thickness are selected based on sewage flow and the scale of treatment facilities. Common specifications include OD110mm to OD630mm.

- Agricultural Irrigation: Smaller diameter and highly flexible coil pipes are typically selected. Common specifications include OD20mm to OD110mm.

- Industrial Pipelines: The appropriate pipe size is selected based on the nature of the conveyed medium and operating conditions. Common specifications include OD63mm to OD400mm.

Conclusion

Understanding and selecting the appropriate HDPE pipe size is key to ensuring the efficient operation of pipeline systems. By considering factors such as pressure rating, flow requirements, and installation environment, users can make the best choices to meet the needs of various applications. The versatility and flexibility of HDPE pipes make them an ideal choice for a wide range of engineering projects.