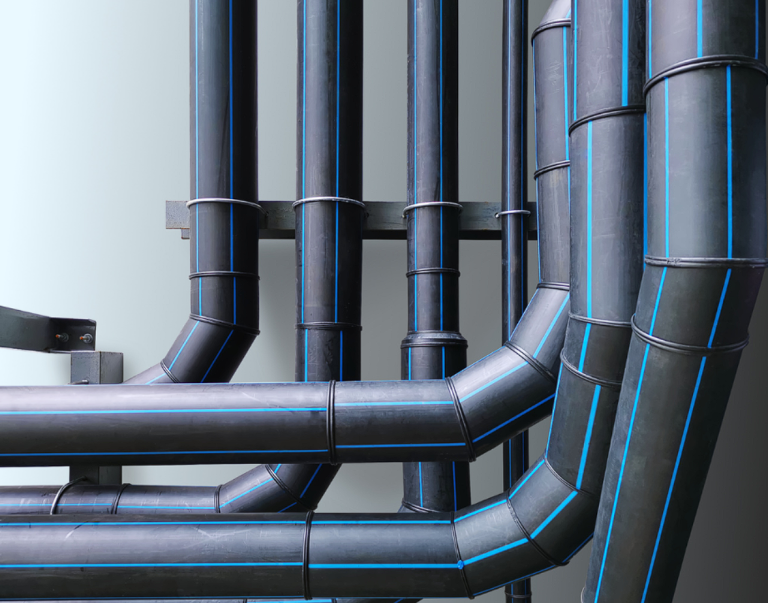

First of all, let’s clarify a question. PE100 and PE80 here refer to the PE raw material grade, not the pipe diameter. PE100 is a 100-grade polyethylene raw material, and PE80 is a 80-grade polyethylene raw material.

PE raw materials are divided into five grades according to international standards: PE32, PE40, PE63, PE80 and PE100. The two main types used for water supply pipelines are PE80 and PE100. The MRS of PE80 reaches 8Mpa, and the MRS of PE100 reaches 10Mpa. In other words, under the long-term hydrostatic strength of polyethylene at 20°C, when used for 50 years, the hoop stress value at which the material will be damaged is PE80 if it is between 8.0-9.99MPa, and PE100 if it is between 1.0-12.49MPa.

The minimum required strength of PE80 is 8.0MPa, while the minimum required strength of PE100 is 10.MPa. Under the same working pressure, the wall thickness of PE100 pipes is thinner because the densities of the two materials are very close. Buried Polyethylene (PE) Pipe System Part 1: Pipe Materials》GB 15558.1-2003 stipulates that the PE pipe series is divided into two series: SDR11 and SDR17.6 according to the standard size ratio (SDR).

1.The difference in raw materials:

PE80 refers to grade 80 polyethylene raw material, and 100 refers to grade 100 polyethylene raw material. The corresponding pressure-bearing capacity of grade 100 is better than that of grade 80. It is made into PE water supply pipe. The maximum pressure of grade 80 is 1.25mpa and that of grade 100 is 1.6mpa. The density of grade 80 is lower than that of grade 100, so grade 80 is also called medium density polyethylene (MDPE) and grade 100 is called high density polyethylene (HDPE).

2.Performance difference:

① Tensile properties: The tensile yield strength of PE100 is 20% higher than that of PE80;

②Impact resistance: The impact resistance of PE100 is higher than that of PE80;

③Bending performance: The flexural modulus of PE100 is 20% higher than that of PE80;

④ Pressure bearing capacity: PE100 has a higher pressure bearing capacity than PE80;

⑤ Fast and slow crack growth resistance: PE100 is higher than PE80.

3.The difference in construction costsUnder the same operating pressure, PE100 grade pipes are thinner and lighter than PE80 grade pipes, reducing engineering costs and construction costs.